It is easy to measure the dimensions of various sections of parts and products based on this data and judge whether they are within tolerances. With image processing, various dimensions can be obtained from captured images.

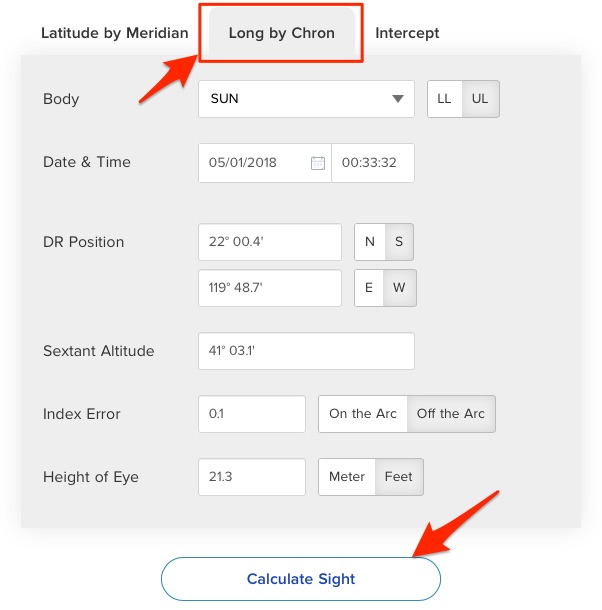

Sight calculation tool manual#

They share the problems of requiring manual operation, and being both time consuming and expensive.

Other methods of dimension measurement include optical comparators, GD&T and profile measurement systems, and 3D measurement systems. However, it does not show accurate measured values. The result of checks with inspection jigs can be used for pass/fail judgment of whether the product is within the tolerance range or not. Measurement using instruments such as microgauges or calipers inevitably involve errors due to individual differences among workers and measurement conditions. In general, the dimensions of parts and products are measured with microgauges or calipers or checked with inspection jigs to ensure that there is no variation in accuracy.

Presence Inspection (Quantity, Missing Parts).History of Machine Vision Camera Lens Lighting Factory Automation (FA) Traceability.Practical Knowledge Concept of Processing Speed Concept of Minimum Detectable Object Size Concept of Shutter Speed.

Sight calculation tool software#

0 kommentar(er)

0 kommentar(er)